Shaping metal like pottery..

About metal spinning

(DIN 8582)

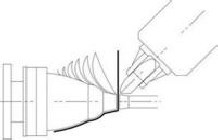

The drawing shows the principles in metal spinning. The initial metal disc is shown above the center line. With the help of a spinning roller, the blank is forced against a mandrel to create the interior dimension of the part. To obtain a perfect finish, the process can be followed by smoothing out the surface on the part. Edges can be cut and rolled in the same operation.

Over recent years, metal spinning has been through a remarkable development and is therefor a very comitive method, both technical and economical.

Olsen is on the leading edge in this field.

Tooling is often less expensive compared to other metal forming methods like deep drawing or die casting. Savings can also be made on material usage.

Materials

All metals that can be cold formed, can be metal spinned. Metal spinning gives a higher material density then e.g. deep drawing.

Metal spinning gives a higher degree of freedom when selecting material because of the unlimited number of shapes that can be metal spinned.

Olsen Metal has experience with all steels and metals including:

Stainless steel

Titanium

Alloys

Special alloys (Hastelloy, Inconel, Paladium,Monel etc.)

Steel

Copper

Brass

Machine capabilities

Olsen Metal use new CNC spinning machines and make parts from diameter 0 – 1200 mm and thickness up to 12 mm in e.g. stainless 1.4404