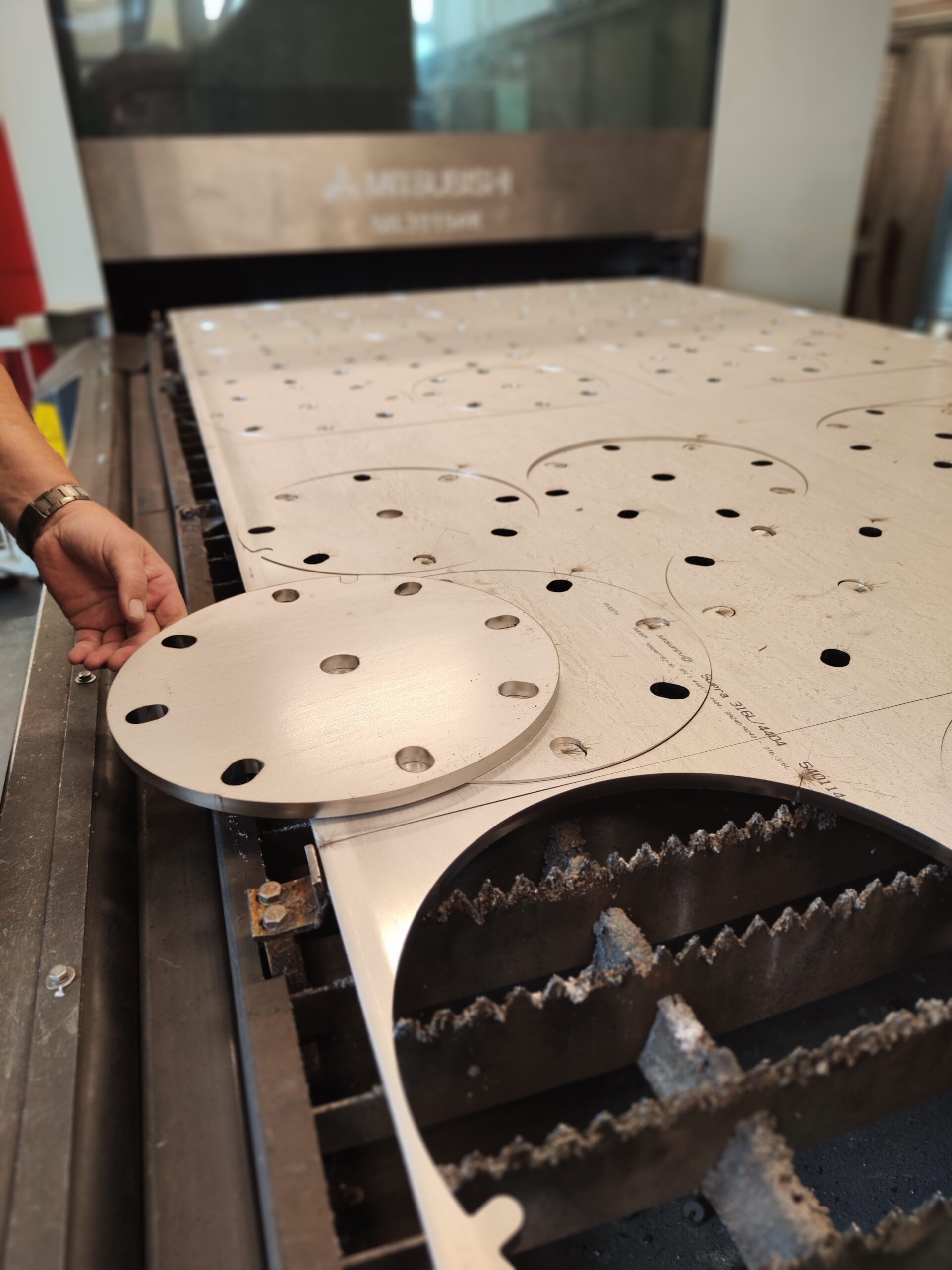

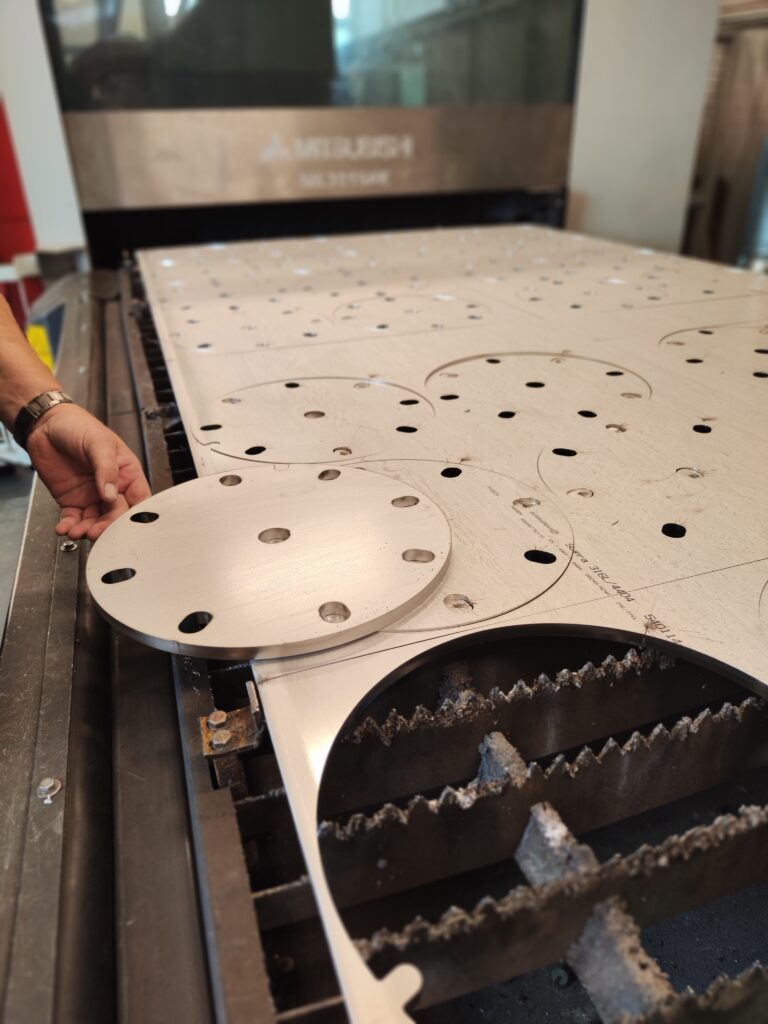

Elevating Metal Fabrication with Advanced CNC Laser Cutting Technology

At Olsen Metal, we understand that our clients are looking for reliable partners who can deliver high-quality metal applications efficiently and sustainably. That’s why we’re thrilled to share that we’ve integrated cutting-edge Mitsubishi CNC laser cutting technology into our operations—an advancement that not only enhances our capabilities but also aligns with our commitment to environmental responsibility.

Benefits of Advanced Laser Cutting for Your Projects

Our new Mitsubishi laser cutting machine is capable of processing stainless steel parts up to 12 mm thick, allowing us to handle larger and more complex projects than ever before. Here’s how this technology benefits you:

- Precision and Quality: The machine’s advanced features, including dynamic focus control and high-speed cutting, ensure that every part we produce meets the highest standards of quality. You can trust that the components you receive will fit perfectly into your applications, saving you time and reducing the need for rework.

- Versatility in Applications: Whether you need standalone components, welded assemblies, or parts prepared for metal spinning, our laser cutting technology can accommodate a wide range of requirements. This versatility allows us to be responsive to your specific project needs, no matter how complex.

- Sustainability Focus: We know that sustainability is a priority for many of our clients. Our new laser cutting machine includes an Ecology Mode that reduces assist gas usage, leading to energy savings and a smaller carbon footprint. By optimizing our production processes, we not only contribute to environmental conservation but also help you meet your own sustainability goals.

Cost Savings Through Efficiency

One of the most significant advantages of our CNC laser cutting technology is its ability to minimize material waste. With precise cuts and efficient planning, we can use less metal while still delivering high-quality applications. This efficiency translates into cost savings for you, allowing you to allocate your budget more effectively.

Additionally, we are committed to using recycled metals in our production processes, further supporting a circular economy. All scrap metal generated during our operations is carefully reused and sent for recycling, ensuring that we all contribute to reducing waste and conserving resources.

Partnering for a Sustainable Future

At Olsen Metal, we believe that the right technology can make a substantial difference in your projects. Our skilled team, including our dedicated industrial technician and CNC laser specialist, Per, operates this state-of-the-art machine with expertise and care. His experience ensures that we can meet your needs with precision, quality, and sustainability at the forefront.

As we continue to invest in advanced technology and sustainable practices, we are excited to be your trusted partner in metal fabrication. Together, we can achieve remarkable results that are good for business and the environment.

For more insights into our sustainability efforts, including our commitment to recycling metal scrap, be sure to check out our blog post here > Sustainable production scrap-metal recycling.