Shaping Metal Masterpieces with Precision and Care

Let Olsen Metal Form Your Next Sheet Metal Application.

Olsen Metal produce to a variety of industries

75+

Years of innovation

10.000+

Completed Metal Spinning Projects

2000+

Leading Metal Spinning Projects

300+

Expert Deep Drawing Projects

Are you ready to choose you metal forming expertise?

At Olsen Metal, we excel in Metal Spinning, Deep Drawing, Welding and more. Choose the service you need and let us with craftmanship, technology and 3D drawings deliver precision and quality tailored applications for your project. We collaborate with companies in Denmark and the rest of Europe.

Sheet metal forming:

- Cost-effective

- High quality results

- Optimal material usage

- Expert knowledge

- Sustainable metals

- Reclycle programs

Why Choose Olsen Metal

Our solutions are innovative

and tailored

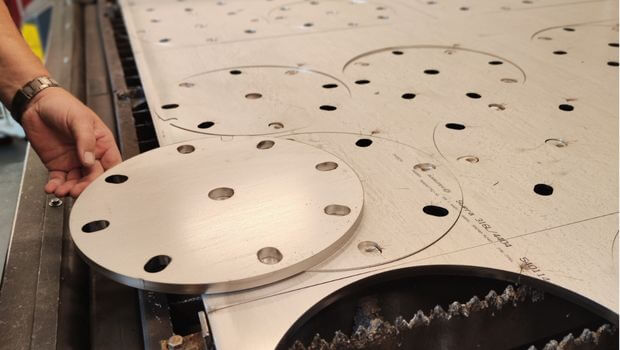

With 3D designed drawings, lasercutting-, CNC- and PNC-machines we give your tailored solutions for prototypes and small series. All with the expertise of metal spinning, deep drawing, welding and more.

Craftmanship and

mordern technology

As a leading sheet metal forming factory our mission is to combine traditional craftsmanship with modern technology. With skilled workers and robot technology we provide fast, accurate and well thought solutions for diverse industries.

We take care

of the future

We take pride in our commitment to sustainability. We are constantly finding new ways to align our operations with the ESG goals, ensuring that we protect the environment, foster social responsibility, and maintain strong governance for a better future.

We are here – Ready to shape your metal work!

Call our office and we will help your tailored applications and designs become a reality.

Latest news from Olsen Metal

GREEN ENERGY

Now we wash your componets with help of natural destilled rainwater!

We collect rainwater to reduce our environmental footprint. Rainwater is natrally destilled, reducing mineral buildup and corrosion in factory equiptment. By using rainwater we are conserving resorces and extending lifespan of our machinery. We meet all our washing needs in production – all from collecting rainwater from the factory rooftop.

NEWS

New laser cutting technology for even bigger projects

Our newest and largest laser machine is capable of cutting stainless steel parts up to 12 mm thick. Now you can plan even bigger and thicker quality projects in the future!

RECYCLE INITIATIVE

Sustainable production – scrap metal recycling

Our scrapmetal gets divided into specific containers and bigger plates get labeled and categorized. With these measures we get a more circulare economy.

Responsible Production

Olsen Metal craft metal applications with future impact

Our craftmanship ensures products that last, all while we minimizing our enviromental footprint.

The 17 goals for sustainable development is an ambition for the whole world towards 2030. Olsen Metal support these goals and wish to contribute where we can!

Check out the world goals that Olsen Metal will influence externally and internally.

We Spin your Requirements into Perfect Fitted Applications

We are proud to use recycled metal for production when possible

Recycling metals helps reduce waste and energy consumption while maintaining the desired performance characteristics in various applications.

Stainless Steel

Same high strength

Stainless steel can be recycled without compromising its high strength, durability, and corrosion resistance. It is frequently used in industries like food processing, medical equipment, and harsh environments.

Aluminium

Energy effecient

Aluminum is widely used in metal spinning and can be recycled without losing key properties such as lightweight, corrosion resistance, and strength. Recycling aluminum is also energy-efficient compared to producing new aluminum.

Copper

Holds its heat transfer properties

Copper can be recycled multiple times without losing its conductivity or malleability. It’s commonly used in electrical and heat transfer applications due to its critical properties.

Brass

An alloy suitable for recycling

Brass, an alloy of copper and zinc, is also suitable for recycling. It maintains its strength, corrosion resistance, and aesthetic qualities, making it popular in decorative and functional applications.

This Stainless Steel can be used as recycled material while retaining the same properties as newly produced stainless steel.

Bertil – Skilled 3D Design Engineer

Craftsmanship and quality assurance

Olsen Metal 3D eksperts make sure your projects meets the highest standards

When working on your new metal spinning projects and applications, 3D drawings are an essential tool. Our experienced 3D expert ensures that even the smallest details are in place, guaranteeing the highest precision.

Accurate 3D drawings reduce the risk of production errors and minimize material waste – helping to keep costs down.

Do you have a project in mind? Contact us to learn how we can help you achieve success.

Laila Glienke

CEO & Founder

I can highly recommend Olsen Metal for their exceptional craftsmanship and reliable service.

Metal applications to a variaty of special needs in different industries

We meet your requierements

Optimized business processes

Designed for speed, on time delivery and agreed quality

Have a question? We have the answers.

Expert answers to your metal forming queries

Contact Our Skilled Metal Experts Today

Olsen Metal A/S

Hadsundvej 8

2610 Rødovre

+45 44 91 55 36

info@olsen-metal.dk

VAT: DK73418216