Metal forming expertise

Ready to elevate your metal fabrication project?

We are a Danish company with decades of metal forming experience. We specialize in metal spinning, deep drawing, and welding. Delivering high quality, sustainable and innovertive solutions.

Contact us now and let us help you shape your vision.

Metal forming – Metal Spinning

Big and small applications. Metal spinning is a cost-effective solution for forming metals. Olsen Metal delivers high-quality results while reduce waste and is energy efficient.

Metal forming – Deep Drawing

Deep drawing at Olsen Metal offers precision and efficiency, ensuring high-quality results for shaping metal sheets with optimal material usage.

Welding and more

Welding and surface treatments provide strong, reliable solutions for metal projects. At Olsen Metal, we ensure high-quality results. TIG, MIG/MAG welding, PMI testing, Heat treatment, Pickling, Sanding, Edge shaping among other treatments.

Why Choose Olsen Metal

Choose Olsen Metal for all your sheet metal forming needs.

Expert Metal Forming Team

Experienced professionals delivering precise metal forming expertise for diverse industries.

Exceptional Craftsmanship and Attention to Detail

Olsen Metal: Expertly crafted sheet metal parts designed to meet your specific needs.

Diverse Metal Forming Services

Comprehensive metal forming services for all your needs. Quality results guaranteed.

Unmatched Customer Satisfaction

Olsen Metal: Transforming Europe’s Industry with Exceptional Sheet Metal Solutions.

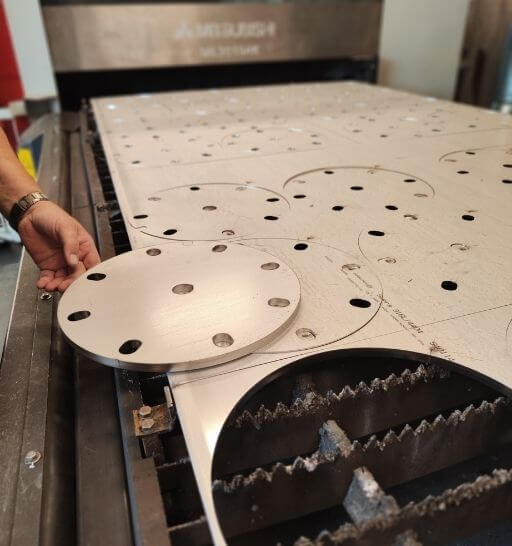

Technologies

What we do best at Olsen

We are experts in sheet metal forming by spinning and flow forming. We combine this process with other forming processes like deep drawing and stamping. We also offer CNC machining, different surface treatments and certified and automated welding.

We are not the best choice for mass produced parts where low price is the only parameter. We keep focus on demanding parts for industry and high end consumer products. Our typical quantity range is between 1 and 25.000 pcs. pr. year.

Metal spinning

Metal spinning is a forming process, where the forming is carried out during rotation. With the help of a spinning roller, the material is forced against a mandrel to create the interior shape of the part. To obtain a perfect finish, the process can be followed by smoothing out the surface. Edges can be cut and rolled in the same operation thus making the production cost effective. Tooling is also inexpencive and makes the process ideal for small quantities.

Over recent years, metal spinning has been through a remarkable development and is therefor a very comitive method, both technical and economical. Olsen is on the leading edge in this field with capability to spinn up to 1200 mm in diameter and material thickness of up to 10 mm stainless steel !

Deep Drawing

We specialize in small quantities and use deep drawing in combination with metal spinning. We are happy to assist in prototyping phase and ramp up phase. Mass production can be offered by partners, that take over when volumne is no longer cost efficient with metal spinning.

Deep drawing is a process where the material is pulled over a form while preventing the material from folding. The process is fast and is ideal for mass production and high demand items. Tooling is required and is normally up to 10 times more expensive than tooling for spinning.

Olsen has the newest in deep draw presses, and can offer a wide selection of press alternatives including Hydro forming.

Welding and other processes

Olsen Metal can deliver finished products including stamping, welding, surface treatment or assembly.

Ready to shape your next metal masterpiece?

Reach out to Olsen Metal today, and our skilled team will guide you through every step. We’re committed to delivering exceptional results and consistently exceeding your expectations.

- Expert Metal Team

- Comprehensive Metal Services

- Exceptional Craftsmanship and Precision

- On-Time Deliveries

- Unmatched Customer Care